Forschungsschwerpunkte

Forschung_Abicht_ch-ano.pdf

(282,5 KB) vom 14.05.2012

Festkörperchemie / Materialwissenschaften

- Herstellung und umfassende Charakterisierung präkeramischer Pulver nach der klassischen Mischoxidmethode als auch nach modernen nasschemischen Verfahren sowie der neuentwickelten Methode der Sprühhydrolyse (stoffliche Basis Bariumtitanat) sowie mittels Mikrowellen-gestützter Hydrothermal- bzw. Solvothermalsynthese

- Synthese core-shell-strukturierter BaTiO3-Precursoren

- Oberflächenmodifizierung von BaTiO3-Ausgangspulvern mittels Laugungsprozessen und „Powder coating“ (Konzept des mikro- und nanochemischen Konstruierens)

- Struktur-Eigenschaftsbeziehungen von Funktionskeramiken

- Einsatz von Mikrowellen zur Synthese von Keramikausgangspulvern und Sinterung von BaTiO3-Keramiken

- Herstellung, Charakterisierung und Anwendung von festen Lösungen im System

- BaTiO3/BaSnO3

- Anionensubstitution (O/N-Austausch) an Bariumtitanat

- Synthese und Charakterisierung nanoskaliger Keramikausgangspulver. Nanostrukturierung von Keramiken

Synthesis of pre-ceramic powders by various methods:

- classical mixed oxide method,

- wet chemical techniques,

- spray hydrolysis (newly developed) and

- extensive characterization of the material obtained.

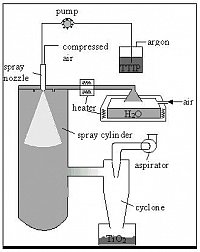

Fig. 1: Scheme of the spray hydrolysis equipment

Please click on the picture for enlargement

Modification of the surface BaTiO3 starting powders by means of coating with preformed secondary phases (TiO2, SiO2, Ba6Ti17O40, CaTiSiO5, ...). This includes investigations of the reactivity of secondary phases against barium titanate. Another feature with a view to surface modification is a leaching process.

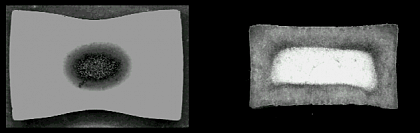

Fig. 2: TEM bright field image of coated BaTiO3 by means of spray hydrolysis

Please click on the picture for enlargement

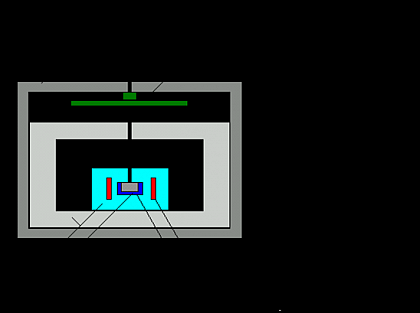

Application of microwave power for the synthesis of BaTiO3 powder as well as the sintering of barium titanate ceramics. A special interest in this field is directed to a secondary phase promoted microwave heating in the sense of microchemical designing.

Fig. 3: Optimized microwave oven for homogeneous sintering of BaTiO3 ceramics

Please click on the picture for enlargement

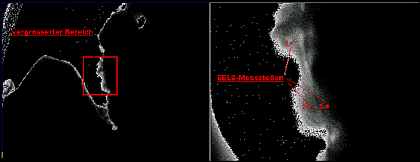

Development and characterization of gradient materials (FGM) with gradients of chemical composition or grain size resulting in gradients of certain (functional) properties.

Fig. 4: Different gradients by means of pure microwave heating (left) and by pure secondary heating (right).

Please click on the picture for enlargement

Last update: Juni 2012